One of the most critical aspects of integrating as complex a system as a display module is to ensure all of your incoming materials are also performing as expected – the famous adage ‘garbage in, garbage out’ is quite applicable here. To do so, display module engineers have a host of tools at their disposal, none more useful than the mechanical control outline (MCO).

For a stable process during mass production, a severely out-of-spec part risks equipment stability or worse, catastrophic failure. While display module equipment is generally cheaper than display fab equipment, a similar concept holds true – equipment downtime means lost revenue for a short period, but equipment failure can have massive consequences for months or more…

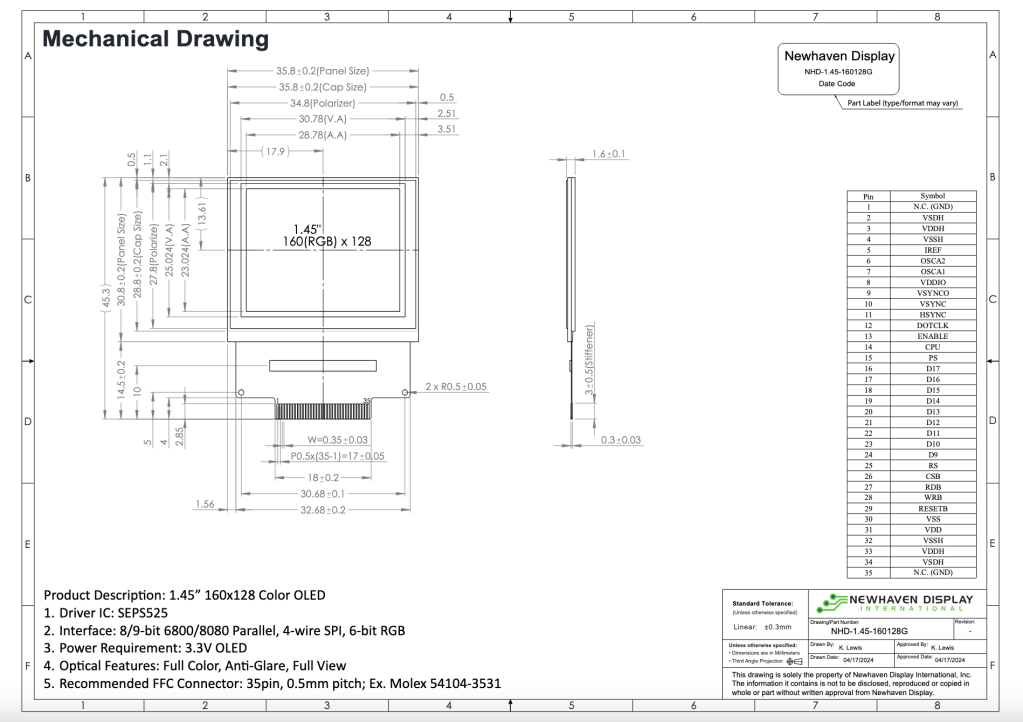

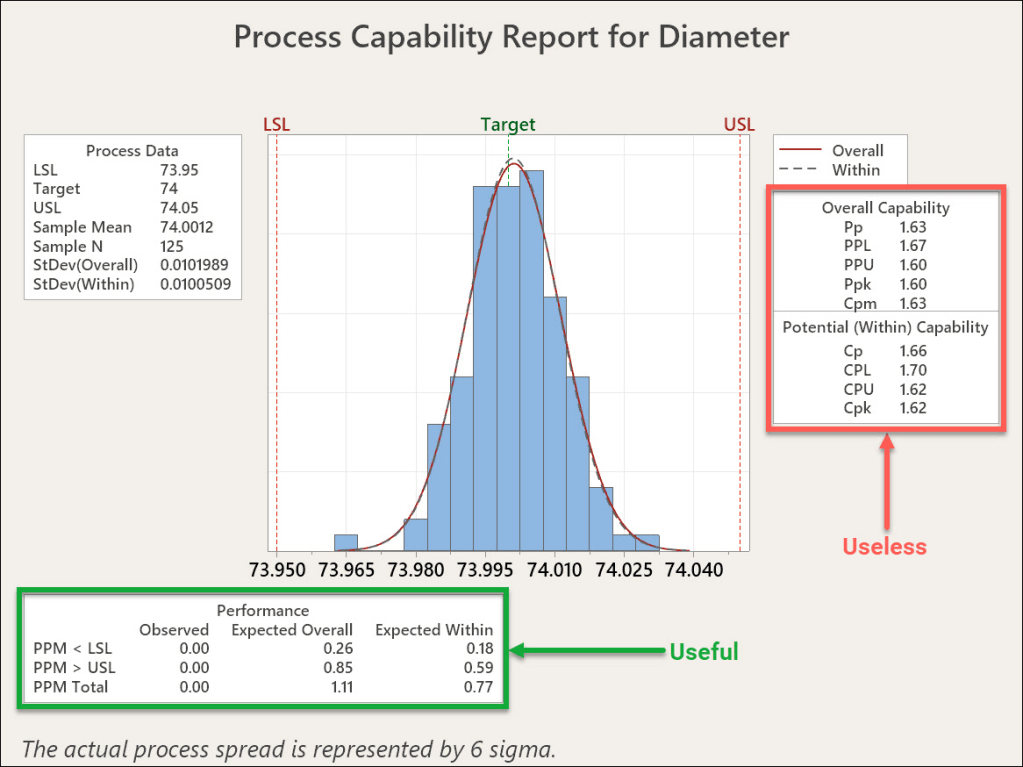

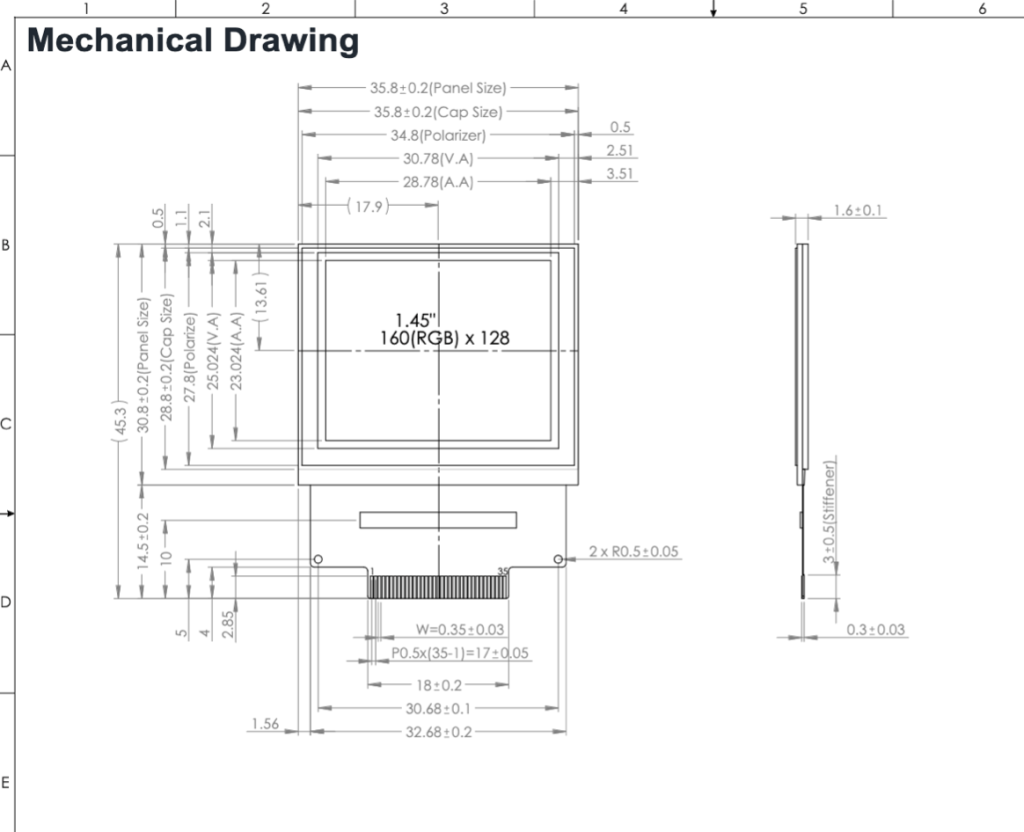

MCOs like the one above help by (1) providing engineers the required tolerancing information for each part, but (2) providing limits that can be used for incoming quality control (IQC) measurements to confirm that mechanical specifications are all being met. Parts will be measured for each critical dimension – critically, these should be also called out in the MCO… – and then a process capability report like the one below will be used to analyze how many defects can be expected in the population.

A process capability report generally focuses on providing the expected yield information, via multiple different metrics that even Six Sigma practitioners struggle to decipher. That said, Cpk is a very common method of evaluating any metric that is normally distributed within an upper and a lower limit. As a rule of thumb, imagine that a dimension from our MCO has a Cpk = 1.33, meaning that we can expect roughly 1 of 1,000,000 parts to be out-of-spec for this particular dimension. 99.999% yield sounds pretty good for a manufacturing process, so we aim for Cpk > 1.33 (even lower failure rates) for all dimensions, processes, and quality checks where applicable.

In the Display Module Manufacturing Certification, we will also explain in more detail the usefulness of Cpk analysis for not just incoming materials, but throughout the entire module process. For now, the key message is simple – don’t put bad parts in, otherwise you’re going to have a bad time.

Leave a reply to Module 3 – Process – Display Training Center Cancel reply